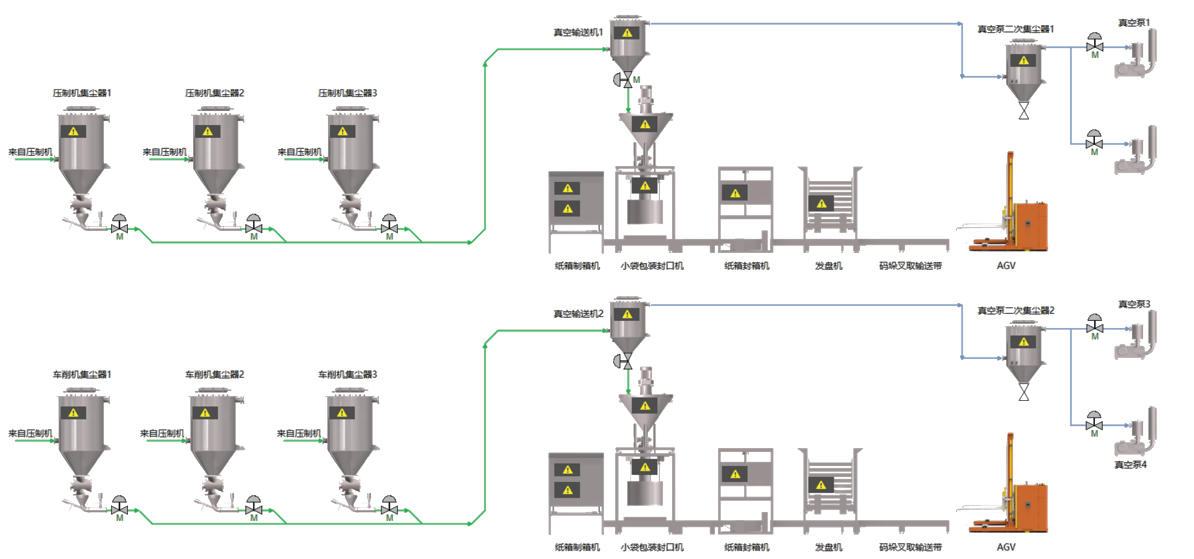

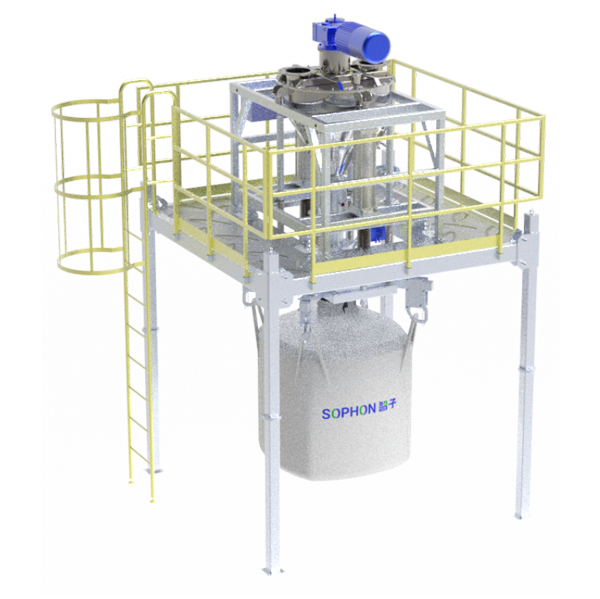

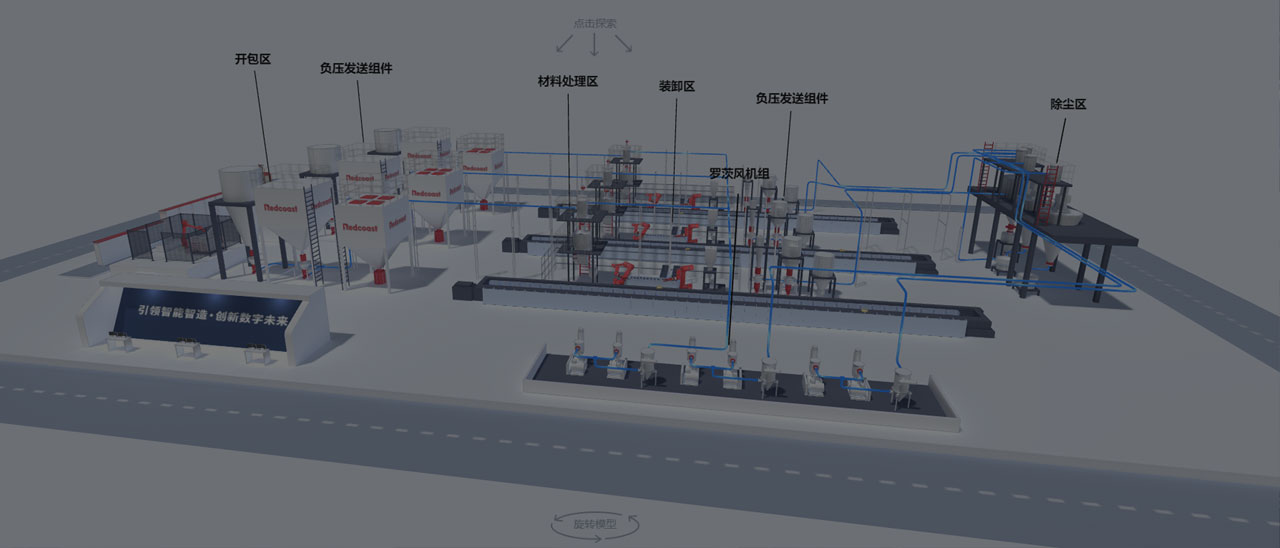

SOPHON provides efficient, eco-friendly, energy-saving, and flexible solutions for material conveyance in the new energy industry, which helps to promote the sustainable development and innovation of the industry.

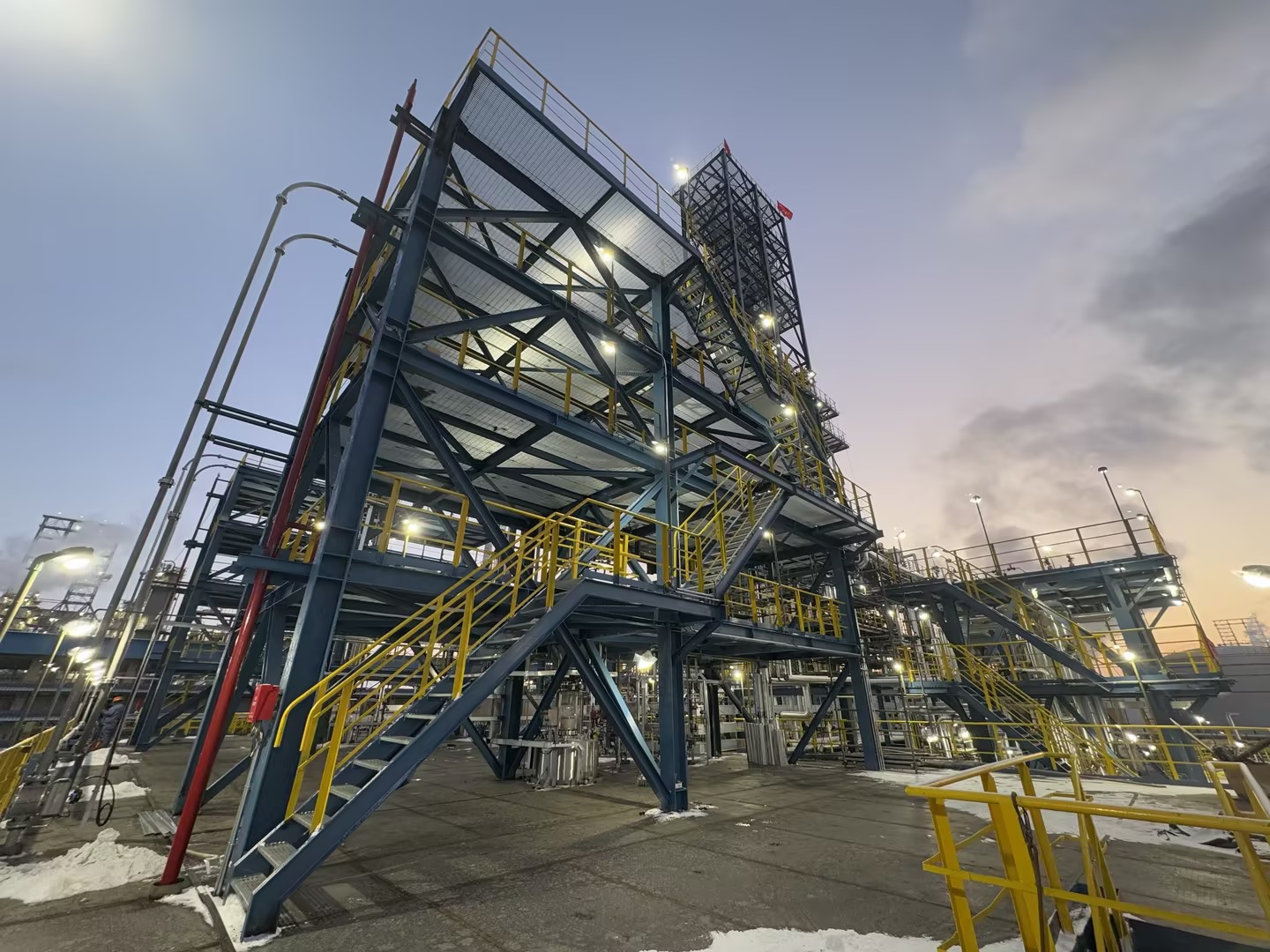

SOPHON satisfies the special process requirements such as mixing, crushing, cooling and dust removal in the chemical industry. Some reaction intermediates sensitive to oxygen and water can be convey- ed with inert gas protection.

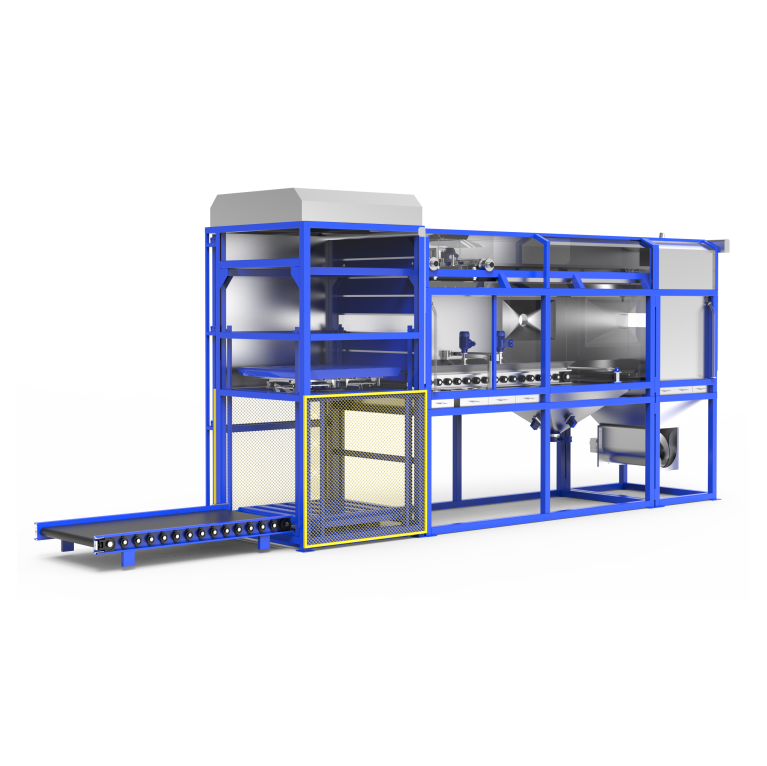

Material conveyance through fully-enclosed pipeline avoids dust and other foreign matter, thus ensuring the cleanliness of raw materials and product safety.

SOPHON provides precise and efficient material conveying systems in the plastic industry that can handle both raw material particles and finished plastics, ensuring the continuity of production process and product quality.

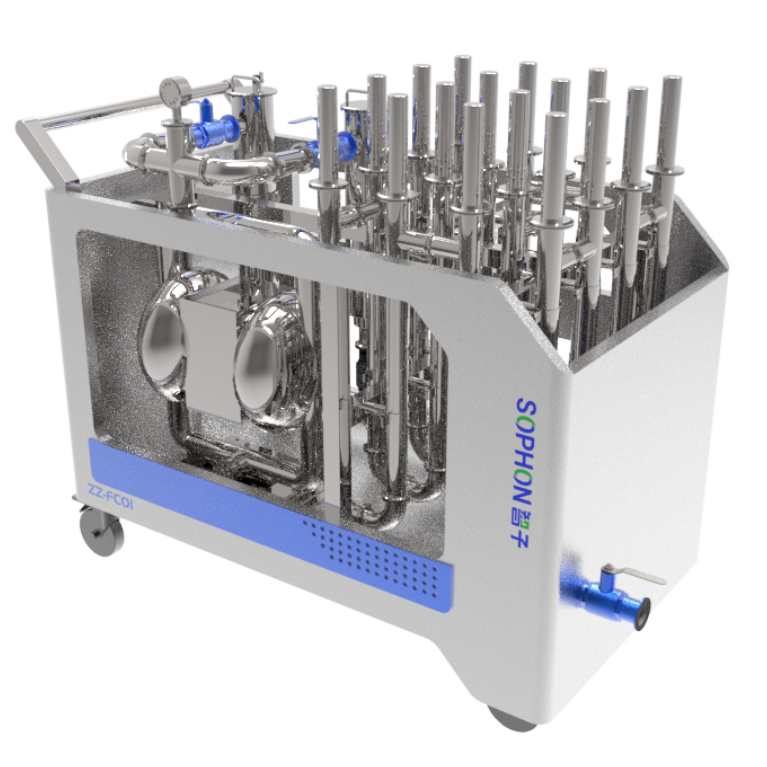

To meet the requirements of high cleanliness and sterility for material conveyance in the pharmaceutical industry, SOPHON adopts special materials and sealing design to effectively prevent cross-contamination and ensure the safety and effectiveness of drug production.

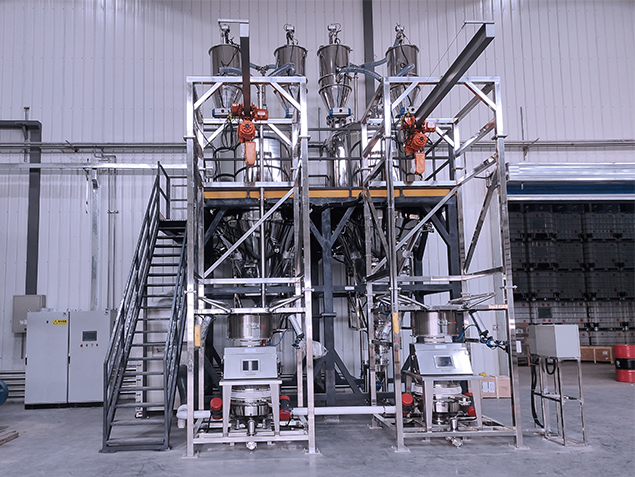

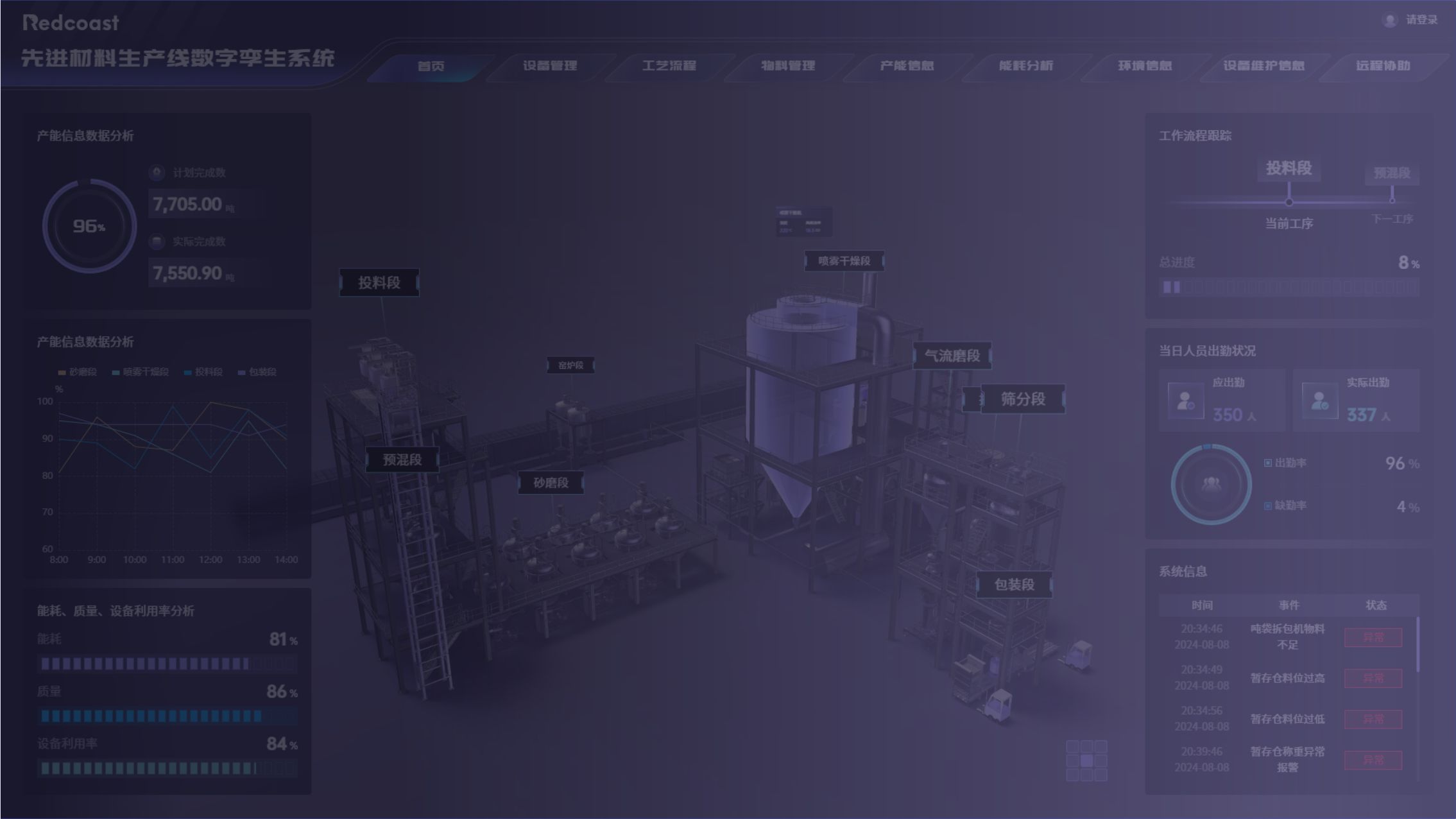

Considering the particularity of the new material industry, SOPHON provides customized material conveying solutions to handle special materials with high temperature, high viscosity and corrosion.

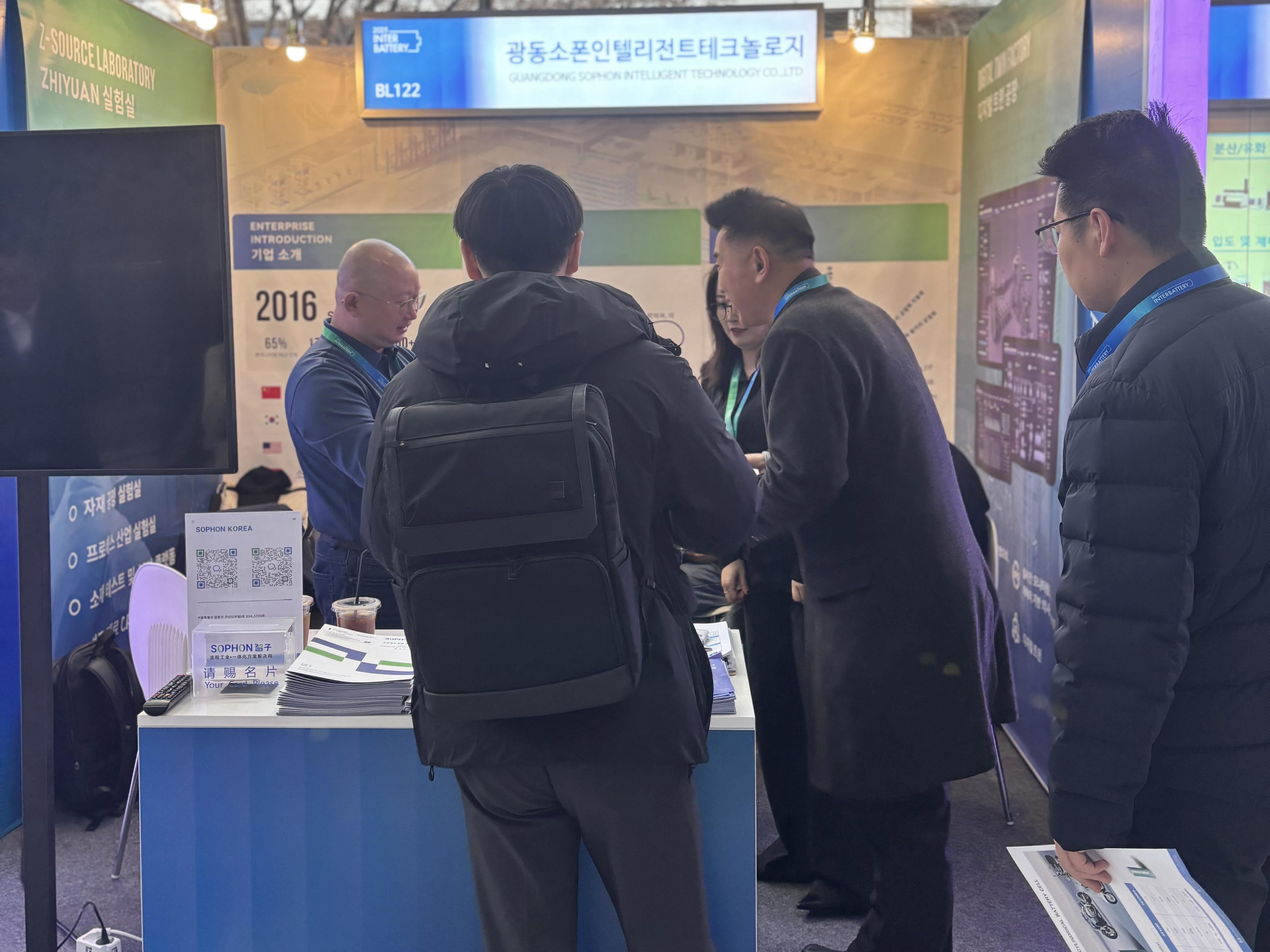

Committed to becoming a world-leading service provider of material handling technologies and upholding forward R&D philosophy in materials and processes, SOPHON provides integrated solutions for the process industry and covers service systems such as advanced design, advanced manufacturing, and advanced operation and maintenance management. Our solutions are widely applied in industries including new energy, new materials, chemical plastics, food, pharmaceuticals, semiconductors, petroleum and petrochemicals.